In modern industrial production, valves are one of the most critical control components in piping systems. Whether in the petrochemical, power, chemical, or pharmaceutical industries, the safe operation of valves is directly related to production safety and stable equipment operation. For a long time, companies generally relied on traditional valve locks to prevent misoperation. However, with the continuous improvement of industrial safety standards, valve mechanical interlocks (VMEs) have gradually become a more reliable and intelligent option. So, what exactly is the difference between VMEs and traditional valve locks? This article will provide a detailed analysis of their functional principles, operation methods, safety, applicable scenarios, and maintenance costs.

1. Overview of Traditional Valve Locks

Traditional valve locks use simple mechanical methods such as locks, cylinders, or padlocks to lock the valve handle or switch, preventing unauthorized operation. These devices have been widely used for decades due to their simple structure and low cost.

Core Features of Traditional Valve Locks

Simple Locking Function: Traditional valve locks primarily prevent unauthorized operation of the valve by physically locking the valve handle. They have a limited function and lack control over the operating sequence. Low Cost: Made of simple materials, typically steel or aluminum alloy, these materials are relatively inexpensive and have low procurement costs.

Easy Installation: The installation process is simple, requiring no complex commissioning, allowing operators to quickly master the system.

Limited Security: This device only prevents unauthorized operation and cannot control the valve operation sequence. Its safety capabilities are limited in high-pressure, flammable, or explosive environments, or in multi-valve operation scenarios.

2. Overview of the Valve Mechanical Interlock

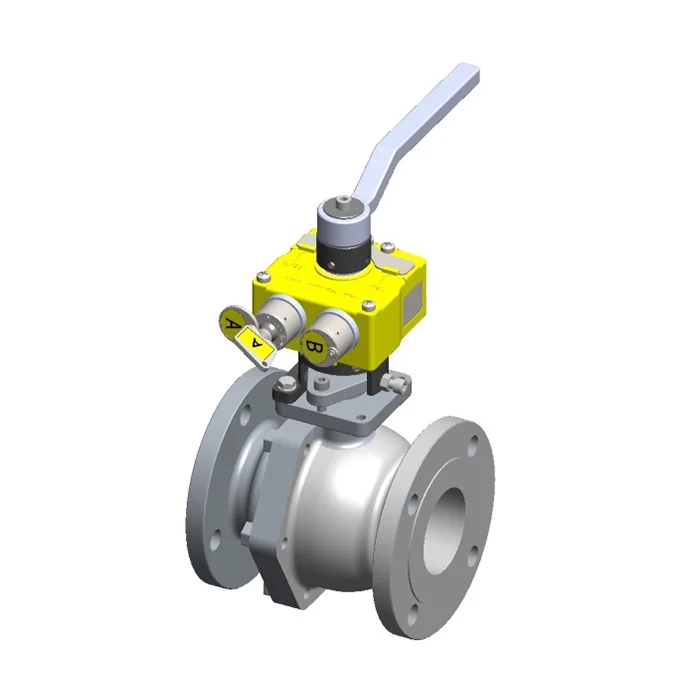

Compared to traditional valve locks, the Valve Mechanical Interlock is a mechanical interlock device that strictly controls the valve operation sequence through physical interlocking. It not only prevents misoperation but also ensures that valves in complex systems are opened and closed according to safe procedures, significantly improving industrial safety.

Core Features of the Valve Mechanical Interlock

Sequential Control: The interlock device can set the sequence of multiple valve operations. For example, in a pipeline system, the main valve must be closed before the branch valve can be opened, preventing liquid backflow or gas leakage.

High Reliability: Its robust mechanical structure requires no electrical power and is corrosion-resistant and high-temperature resistant, making it suitable for harsh industrial environments. Flexible Customization: It can be customized based on valve type, size, and operating procedures to meet the needs of complex industrial systems.

High Safety: It prevents accidents caused by operational errors and is the preferred safety protection solution for petrochemical, power, pharmaceutical, and high-pressure systems.

3. Differences between Valve Mechanical Interlock and Traditional Valve Locks

The following compares the two in several key dimensions:

3.1 Function and Operation Mode

Traditional valve locks only lock the valve handwheel, preventing the operator from opening the locked valve, but also provide no control over the valve operation sequence.

Valve Mechanical Interlock: Not only does it lock the valve, it also interlocks the operation according to a set sequence, ensuring that the valve opens and closes within a safe process. In multi-valve operating systems, mechanical interlocks effectively prevent hazards caused by incorrect sequence operation.

3.2 Safety

Traditional valve locks: Safety relies on the lock itself and operator awareness, and cannot prevent the risks of incorrect sequence or complex combination operations.

Valve Mechanical Interlock: Through a physical interlocking mechanism, the operation sequence is automatically limited. Even inexperienced operators can avoid dangerous operations, significantly improving system safety.

3.3 Applicable Scenarios

Traditional Valve Interlocks: Suitable for simple single-valve or low-risk piping systems, primarily used to prevent unauthorized operation.

Valve Mechanical Interlocks: Suitable for high-pressure, high-temperature, flammable and explosive systems, or multi-valve systems, such as petrochemical reactors, steam pipelines, power condensation systems, and other complex industrial environments.

3.4 Installation and Maintenance

Traditional Valve Interlocks: Easy to install and maintain, requiring little professional training.

Valve Mechanical Interlocks: Installation requires an interlocking scheme designed based on the valve type and piping layout. Maintenance requires regular inspection of the interlock mechanism, lock pins, and gears for wear, but this comes at the cost of increased safety.

3.5 Cost-Effectiveness

Traditional Valve Interlocks: Low initial purchase cost, but potential safety hazards in high-risk environments can lead to significant losses.

Valve Mechanical Interlocks: Relatively high initial cost, but in the long term, they offer a more cost-effective solution by reducing accident risks, downtime losses, and maintenance costs.

4. Advantages of Valve Mechanical Interlocks in Industrial Applications

Preventing Accidents Due to Misoperation: In complex process systems, incorrect operation can lead to liquid backflow, gas leakage, or even explosions. Mechanical interlocks ensure valves operate in a safe sequence.

Improves operational efficiency: Operators no longer need to repeatedly confirm valve sequence, reducing human error and downtime.

Adaptable to harsh environments: Corrosion-resistant, high-temperature resistant, and requiring no power supply, they are suitable for environments such as chemical, petrochemical, and high-temperature steam pipelines.

Flexible customization and scalability: Multi-point interlocks, chain interlocks, or combination interlocks can be customized to meet individual needs based on the complexity of the industrial system.

Compliant with industrial safety regulations: An increasing number of industrial safety standards require sequential interlocks for critical piping systems, making mechanical interlocks a compliant option.

5. Recommendations for Selecting a Valve Mechanical Interlock

When selecting a mechanical interlock, companies should consider the following factors:

Valve type and size: Ensure the interlock is compatible with existing valves, including handwheel diameter, valve mounting method, and material.

Operating environment: High-pressure, high-temperature, and corrosive environments require durable materials such as stainless steel or high-strength alloys.

Operational complexity: For multi-valve system operations, select a device that supports multi-point or chain interlocks.

Brand and After-Sales Service: High-quality brands offer professional customized solutions and technical support to ensure long-term stable operation.

6. Summary

The key difference between a valve mechanical interlock and traditional valve locks is that the former not only locks the valve but also controls the operating sequence, adapting to complex industrial environments and offering significantly greater safety and reliability than traditional locks. In high-risk industries, mechanical interlocks are not only essential for improving safety management but also a wise choice for mitigating potential economic losses and ensuring production continuity.

Traditional valve interlocks are suitable for low-risk or single-valve systems. However, for high-pressure, high-temperature, flammable and explosive systems, or multi-valve systems, valve mechanical interlocks are a core tool for ensuring safe production and compliance with industrial regulations. By choosing high-quality brands and appropriately customized solutions, companies can achieve efficient and controllable valve operation management while improving safety.

Nudango, a professional valve mechanical interlock manufacturer, has many years of experience in the research and development and production of industrial safety devices. The company's product offerings cover a wide range of valve types and interlocking solutions. Nudango can design custom interlocking devices based on the customer's piping system, ensuring safe and reliable valve operating sequences. Nudango's mechanical interlocking devices are heat-resistant, corrosion-resistant, and robust, making them widely used in high-risk industries such as the petrochemical, power generation, chemical, and pharmaceutical industries. With strict quality control and comprehensive after-sales service, Nudango helps companies improve valve operation safety, reduce accident risks, and achieve efficient and controllable industrial production management.

www.nudango.com

nudango