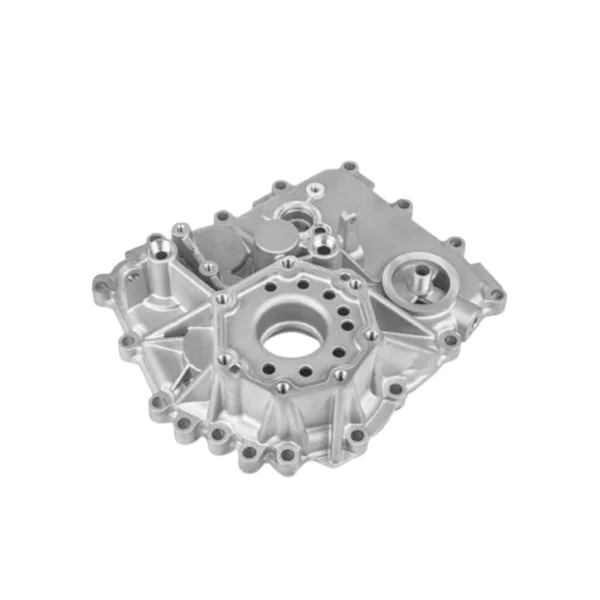

Die casting is a critical manufacturing process in the automotive and industrial machinery sectors, particularly for the production of complex components like gear box covers. These components are essential for housing gears and bearings, maintaining lubrication, and ensuring the structural integrity of transmission systems. High precision in die casting is not merely a desirable attribute—it is an absolute necessity. Any defect or dimensional deviation can compromise the functionality, safety, and durability of the entire gearbox assembly. In this blog post, Okin, a high quality CNC machining parts manufacturer, will share the quality control of high precision gear box cover die castings for sale.

1. Understanding the Functional Requirements of Gear Box Covers

Gear box covers are subject to rigorous operational demands. They must withstand mechanical stress, resist thermal expansion, and offer sealing capabilities to prevent lubricant leakage. Consequently, the die casting process must meet tight tolerances, maintain material consistency, and avoid internal and surface defects.

Key performance requirements include:

* Dimensional accuracy: Typically in the range of ±0.05 mm or tighter for critical interfaces.

* Flatness and parallelism: Necessary for proper gear alignment and bearing support.

* Surface finish: Smooth surfaces are essential for sealing areas and aesthetic standards.

* Mechanical strength and ductility: Ensures the component can endure dynamic loads and impacts.

* Thermal stability: Required to resist warping or deformation under engine or motor heat.

2. Material Selection and Control

The majority of gear box covers are manufactured from aluminum or magnesium alloys due to their excellent strength-to-weight ratios, corrosion resistance, and castability.

Material control strategies include:

* Chemical composition verification: Employing spectrometers to ensure alloy conformity to standards (e.g., ASTM B179 for aluminum die casting alloys).

* Ingot certification: Requiring supplier certifications for each batch and conducting random sampling.

* Melt quality monitoring: Removing dross, controlling hydrogen content, and maintaining melt temperature to prevent porosity and oxide inclusions.

* Alloy modification and grain refinement: Addition of modifiers like strontium for aluminum-silicon alloys to refine microstructure and improve mechanical properties.

3. Tooling and Mold Quality Assurance

The precision of the die tooling directly influences the final casting quality. Any wear, misalignment, or thermal distortion in the die can lead to dimensional inaccuracies or casting defects.

Tooling QC steps include:

* Mold flow simulation: Prior to tooling fabrication, simulate metal flow and solidification to optimize gate and runner design.

* Die temperature control: Use of thermocouples and temperature sensors to ensure consistent mold temperatures, minimizing warping and improving surface finish.

* Preventive maintenance schedules: Regular inspections for erosion, cracks, or buildup of flash in the die cavities.

* Surface coatings: Use of PVD or CVD coatings to increase die life and reduce sticking or erosion.

4. In-Process Control During Die Casting

Real-time monitoring and control during the die casting process are crucial to maintain consistent product quality.

Key in-process control parameters:

* Injection velocity and pressure: Must be optimized to ensure complete cavity fill and to avoid turbulence, which can cause air entrapment and porosity.

* Die temperature and cooling rate: Thermal sensors and controlled cooling circuits manage thermal gradients, minimizing internal stresses.

* Vacuum-assisted die casting: Vacuum systems remove air from the die cavity, drastically reducing porosity and improving mechanical properties.

* Lubrication systems: Controlled spray systems for die lubricants prevent cold shuts and soldering issues.

Data from these processes are often captured using SCADA systems or PLCs to enable traceability and statistical process control (SPC).

5. Post-Casting Quality Inspection and Testing

Once the part is cast, it undergoes a series of rigorous inspections and testing procedures to verify compliance with specifications.

Inspection methods include:

5.1 Visual Inspection

* Purpose: To identify surface defects such as cracks, cold shuts, misruns, flash, or blisters.

* Method: Manual or camera-based systems with AI vision algorithms.

5.2 Dimensional Inspection

* Tools: Coordinate Measuring Machines (CMMs), optical comparators, and laser scanners.

* Targets: Key dimensions such as bearing bore diameters, bolt hole patterns, flatness, and wall thicknesses.

* Tolerance verification: Adherence to geometric dimensioning and tolerancing (GD\&T) standards like ASME Y14.5.

5.3 Non-Destructive Testing (NDT)

* X-ray inspection: Detects internal porosity, shrinkage cavities, and inclusions. Automated X-ray systems offer 3D CT scanning capabilities for critical parts.

* Dye penetrant testing (DPT): Identifies surface cracks and porosity not visible to the naked eye.

* Ultrasonic testing: Measures wall thickness and detects internal flaws.

5.4 Mechanical Testing (on sampled parts)

* Tensile and hardness testing: Confirms material strength and heat treatment effectiveness.

* Fatigue testing: In high-performance applications, fatigue resistance is critical.

6. Machining Quality Control

Most gearbox covers require secondary machining operations, such as drilling, tapping, and milling, especially in areas that demand higher precision than the casting process can achieve.

QC steps during machining:

* Pre-machining inspection: Ensures the casting is within stock allowances and free of defects.

* CNC program verification: Simulations and dry runs to prevent tool path errors.

* In-line gauging systems: Use of probe systems and automatic gauging to ensure hole locations, diameters, and depths are within spec.

* Tool wear monitoring: Predictive maintenance systems based on vibration or force monitoring reduce the risk of dimensional out-of-tolerance parts.

7. Leak and Pressure Testing

As gearbox covers often serve as oil-tight enclosures, leak testing is a vital aspect of quality control.

Common testing methods:

* Pressure decay testing: Pressurizing the part with air and monitoring pressure loss over time.

* Helium mass spectrometry: Offers higher sensitivity for detecting microscopic leaks.

* Water immersion testing: A cost-effective but less precise method used for lower-spec applications.

8. Final Inspection and Certification

Before shipment, each part must pass a final inspection process and be documented for traceability.

Final QC steps include:

* Part marking and traceability: Laser marking or QR codes linked to batch records and inspection reports.

* Packaging inspection: Ensures components are protected from mechanical damage or corrosion during transport.

* Documentation: Compilation of certificates of conformance, test reports, and statistical quality records.

9. Continuous Improvement and Feedback Loop

A robust quality control system is not static; it evolves based on data analytics and feedback.

Strategies include:

* Pareto analysis of defects: Identifying the most frequent causes of rejection and addressing root causes.

* SPC and Six Sigma methodologies: Continuous monitoring of process capability indices (Cp, Cpk) to reduce variability.

* Design of Experiments (DoE): Systematically optimizing process parameters to improve yield.

* Customer feedback integration: Quality issues discovered in assembly or in-field applications must be traced back to root causes in the casting or machining stages.

Conclusion

High precision gear box cover die castings demand an end-to-end quality control approach—from raw material verification through to final inspection and continuous feedback. Each step in the process presents unique challenges that require technical solutions, standardized procedures, and advanced monitoring technologies. As automotive and industrial standards become more stringent, and as electric vehicle (EV) applications place new demands on transmission components, the emphasis on defect-free, dimensionally accurate, and high-performance castings will only increase. By integrating meticulous quality control protocols, manufacturers can ensure that their gear box covers meet and exceed these evolving expectations.

www.okinmachining.com

Okin