In modern industrial production, labeling is an indispensable part of product packaging, and its automation level directly affects production efficiency and product image. Especially in the food, beverage, medicine, chemical, daily chemical and other industries, round bottles are the most common form of container, and their labeling needs are particularly extensive and frequent. As an efficient equipment specifically designed to meet this demand, the automatic round bottle labeling machine is gradually becoming one of the preferred equipment for various factories to improve their automation level. This article will conduct a comprehensive analysis of the definition, working principle, core advantages, application scenarios, selection recommendations, and maintenance of the automatic round bottle labeling machine to help you gain a deeper understanding of this intelligent device.

1. What is a automatic round bottle labeling machine?

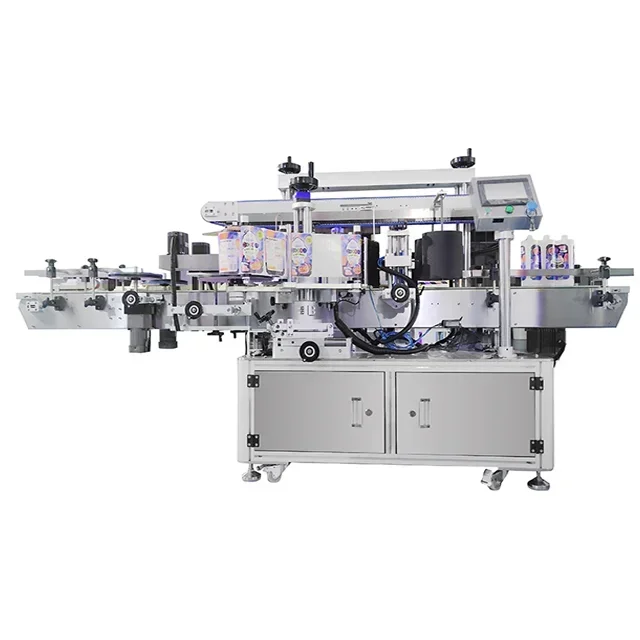

The automatic round bottle labeling machine is a device used to automatically attach labels to the outer surface of a round bottle. It can realize a series of fully automated operations such as bottle conveying, positioning, label peeling, labeling and pressing. Compared with manual or semi-automatic labeling equipment, it has higher speed, more stable precision, and lower labor costs. It is an important part of modern assembly line production.

Applicable container types include: plastic round bottles, glass bottles, metal cans, cans, PET bottles, medicinal bottles, reagent bottles, etc., and the label materials are mostly self-adhesive labels, transparent labels, PE labels, PVC labels, etc.

2. Working principle of automatic round bottle labeling machine

Automatic round bottle labeling machine usually includes the following core structures: bottle feeding device, positioning device, label stripping device, label pressing device, control system and sensor system. Its basic working process is as follows:

Bottle feeding: The round bottles to be labeled are sent to the labeling area in an orderly manner through a conveyor belt or roller.

Bottle body positioning: Some models are equipped with bottle separation devices and orientation mechanisms to ensure that each bottle is spaced consistently and correctly positioned.

Label separation: The label roll is sent out by the label stripping mechanism, the label backing paper is automatically rewound, and the front end of the label is to be pasted.

Automatic labeling: After the sensor senses that the bottle has arrived, the labeling device automatically presses the label onto the bottle body, and cooperates with the rotating roller when necessary to achieve surrounding labeling.

Pressing and fixing: The label is firmly pressed by the labeling device to avoid wrinkling, bubbling or falling off.

Bottle out: The bottle that has been labeled continues to be transported to the next process.

The whole process is precisely synchronized and logically judged by the PLC program control system to ensure the consistency and efficiency of labeling.

3. Advantages of automatic round bottle labeling machines

High efficiency and high precision

The automatic round bottle labeling machine can label 40-150 bottles per minute (depending on the equipment model and product specifications), which is much higher than manual or semi-automatic methods. At the same time, through high-precision photoelectric sensors and servo motor systems, the label attachment position is guaranteed to be accurate and consistent, with an error of less than ±1mm.

Strong adaptability

Whether it is plastic bottles, glass bottles, or round bottles of different diameters and heights, the equipment can adjust the labeling parameters according to the bottle type, and even supports multiple labeling modes such as double labels, wraparound labels, and positioning labels.

Convenient operation

Equipped with a human-computer interactive touch screen, parameter settings, product switching, and fault alarms are clear at a glance. Most models support label storage function, which can quickly call historical settings, greatly improving production switching efficiency.

Save manpower

The traditional labeling method relies on a lot of manpower, which is not only inefficient but also prone to errors. The automatic round bottle labeling machine realizes "one person watching multiple machines", significantly reducing labor costs and improving management efficiency.

Improve product image

Neat and beautiful labels directly affect consumers' first impression. Automated labeling enables each product to present a standardized and professional packaging image, which helps to shape the brand image and enhance market competitiveness.

4. Application of automatic round bottle labeling machine

The automatic round bottle labeling machine is suitable for almost all industries that use round bottle packaging, including but not limited to:

Food industry: mineral water, beverages, condiments, juice bottles, honey jars, sauce bottles, etc.;

Pharmaceutical industry: oral liquid bottles, medicine bottles, alcohol bottles, nutrient solution bottles, etc.;

Cosmetics industry: shampoo bottles, skin care bottles, essential oil bottles, spray bottles, etc.;

Chemical industry: detergent bottles, lubricant bottles, reagent bottles, etc.;

Daily necessities industry: laundry detergent bottles, insecticide bottles, air freshener bottles, etc.

5. Key parameters for purchasing automatic round bottle labeling machines

During the procurement process, enterprises should focus on the following aspects according to their own product characteristics and production needs:

Labeling speed: the appropriate model should be selected according to production capacity requirements;

Labeling accuracy: for high-end products, accuracy is crucial;

Applicable bottle type range: whether the equipment supports all current bottle types or bottle types that may be expanded in the future;

Label specifications: whether the equipment is compatible with the label size and material used;

Labeling method: is it full-circle labeling, half-circle labeling, double label labeling or positioning labeling?

Operating system: whether it has automatic fault diagnosis, parameter storage, user-friendly interface and other features;

After-sales service: the equipment has a long service life, and good technical support and accessories supply are particularly critical.

6. Daily maintenance and troubleshooting suggestions

Although the structure of the automatic round bottle labeling machine is relatively mature, dail

www.beiltpack.com

Shanghai BEILT Machinery Equipment Co., Ltd