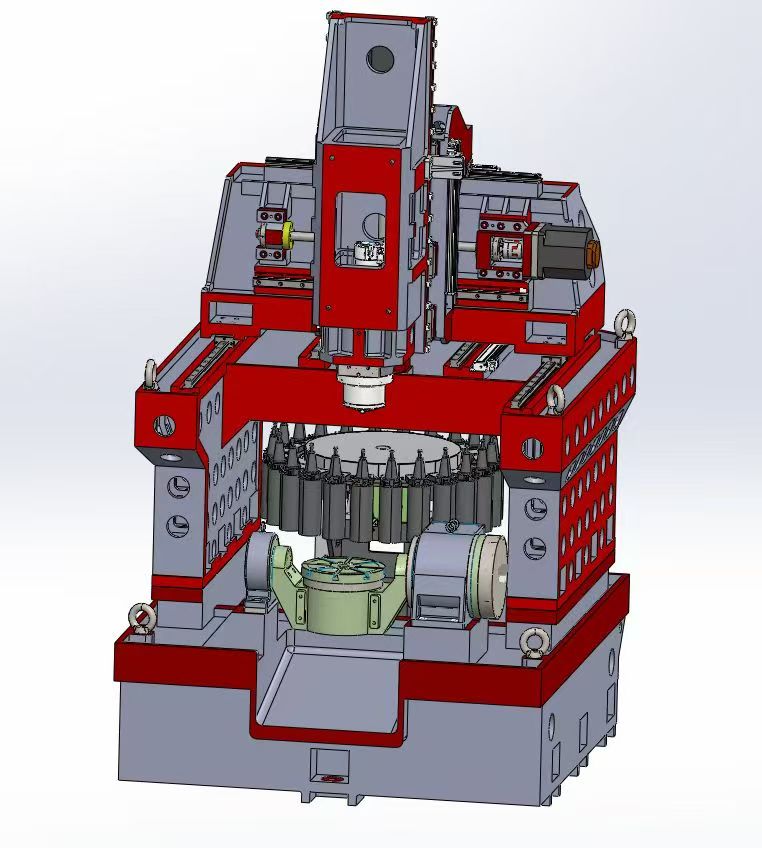

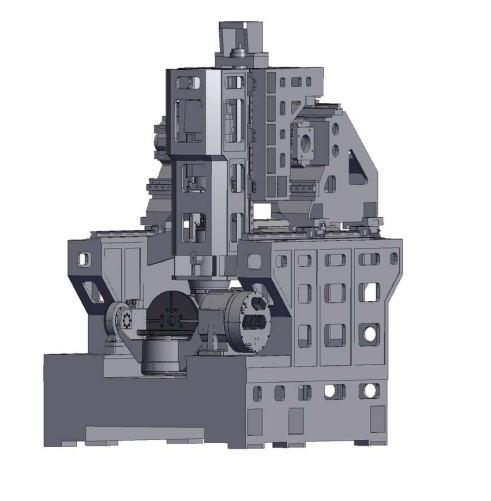

Five-axis cradle machining is revolutionizing modern manufacturing by offering precision, flexibility, and efficiency that traditional machining methods cannot match. This advanced technology enables cutting, drilling, and shaping of complex parts with fewer setups, making it an essential tool across various industries. Companies like Suzhou Zhiquan Electromechanical Equipment Co., Ltd., which specializes in the production and sales of CNC machining centers, wire-cutting machines, EDM machines, milling machines, and related equipment, are key providers of the machinery that makes five-axis machining possible. Their solutions enable manufacturers worldwide to remain competitive in demanding markets.

Understanding Five-Axis Cradle Machining

Five-axis cradle machining refers to the ability of a machine tool to move a workpiece or cutting tool along five different axes simultaneously. These include the traditional X, Y, and Z linear axes, as well as two additional rotary axes. This multi-directional control allows for the machining of highly intricate shapes and contours with exceptional precision. Unlike three-axis machining, where repositioning is often required, five-axis systems can reach difficult angles in a single setup.

This capability significantly reduces production time and ensures higher accuracy. With companies such as Suzhou Zhiquan Electromechanical Equipment Co., Ltd. manufacturing advanced CNC machining centers, businesses gain access to highly reliable machinery tailored for complex operations.

Role in Aerospace Engineering

The aerospace sector demands parts with uncompromising precision and reliability. From turbine blades to aircraft structural components, every piece must meet strict tolerance requirements. Five-axis cradle machining is invaluable here because it allows for smooth, continuous machining of aerodynamic surfaces. Components such as impellers, engine housings, and turbine disks benefit greatly from this technology.

By utilizing CNC machining centers designed by Suzhou Zhiquan Electromechanical Equipment Co., Ltd., aerospace manufacturers achieve the consistency and surface finish required for high-performance applications. Reduced manual intervention also minimizes the risk of human error, which is crucial in safety-critical aerospace components.

Importance in Automotive Manufacturing

Automotive companies face constant pressure to innovate while keeping costs manageable. Five-axis machining helps them meet these demands by enabling the creation of lightweight, high-strength parts. Complex engine components, transmission systems, and prototype models can all be efficiently produced with minimal waste.

For example, cylinder heads and suspension parts require multiple angles of machining, which five-axis cradle systems can accomplish in fewer setups. Suzhou Zhiquan Electromechanical Equipment Co., Ltd. supplies equipment that enhances the efficiency of such processes, helping automotive firms shorten production cycles and accelerate time-to-market for new models.

Contribution to Medical Device Production

Medical devices often involve intricate geometries that must be manufactured with absolute precision. Five-axis machining is instrumental in producing surgical instruments, orthopedic implants, dental prosthetics, and diagnostic equipment parts. The ability to cut titanium, stainless steel, and biocompatible polymers into precise, customized shapes ensures that patients receive reliable and safe medical solutions.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. supports this industry by providing CNC machining centers and EDM machines capable of handling the delicate requirements of medical device production. Their technology allows for the creation of patient-specific implants and tools with exceptional accuracy and repeatability.

Impact on Energy Equipment Manufacturing

Energy production equipment, whether for traditional power plants or renewable sources, requires robust components capable of withstanding extreme conditions. Five-axis cradle machining is applied to parts such as turbine rotors, compressors, and specialized valves. By machining these complex geometries efficiently, manufacturers improve performance and extend the operational lifespan of equipment.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. plays a crucial role by offering precision machining equipment that can handle high-strength materials like nickel alloys and stainless steels commonly used in the energy sector. This ensures that power generation remains efficient and reliable.

Use in Mold and Die Making

Mold and die production is another area where five-axis machining proves indispensable. The intricate contours and cavities required for plastic injection molds, die-casting molds, and stamping dies demand advanced machining capabilities. With five-axis cradle machining, toolmakers can produce these complex geometries with minimal finishing work.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. provides milling machines and EDM systems that complement five-axis technology, ensuring superior surface finishes and high precision. This reduces production time while enhancing mold durability, making it easier for manufacturers to produce high-quality products consistently.

Advantages in Shipbuilding and Marine Engineering

Marine engineering requires large, durable components that can withstand harsh sea conditions. Five-axis cradle machining is particularly valuable for creating propellers, pump housings, and structural parts for ships. Its ability to work on large-scale, complex surfaces ensures both accuracy and durability.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. supports the marine industry with reliable machining centers that handle tough materials like bronze and stainless steel, essential for marine environments. Their equipment helps shipbuilders meet stringent international standards for safety and performance.

Applications in Electronics Manufacturing

Electronics companies rely heavily on miniaturized, precise components to power devices such as smartphones, computers, and communication systems. Five-axis machining allows for the production of compact, intricate parts such as connectors, housings, and heat sinks.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. offers advanced CNC machining centers that meet the high demands of electronics manufacturing. Their systems deliver excellent repeatability and micro-level precision, enabling manufacturers to maintain product quality while scaling production.

Conclusion

Five-axis cradle machining has established itself as a cornerstone of advanced manufacturing. Its ability to handle complex geometries, improve efficiency, and reduce manual intervention makes it indispensable across aerospace, automotive, medical, energy, mold making, marine, and electronics industries. Companies such as Suzhou Zhiquan Electromechanical Equipment Co., Ltd. play a pivotal role by supplying the world with state-of-the-art CNC machining centers, EDM machines, wire-cutting machines, and milling equipment that enable these applications.

As industries continue to seek higher levels of precision and productivity, the importance of five-axis cradle machining will only grow. By embracing this technology, businesses can ensure their competitiveness and deliver superior products to markets worldwide.

Enhancing Precision Manufacturing with Five-Axis Cradle Machining Technology

www.szzhiquan.com

Suzhou Zhiquan Electromechanical Equipment Co., Ltd.