Efficient cable management is a cornerstone of modern manufacturing, data centers, electrical installations, and industrial automation. Poorly organized cables can lead to safety hazards, reduced airflow, difficult maintenance, and even system downtime. Traditional manual cable-tying methods, while straightforward, often result in inconsistent results, slow assembly, and repetitive strain on workers. Automatic cable‑tie machines provide a reliable solution, enabling fast, consistent, and high-quality cable bundling in a variety of professional environments.

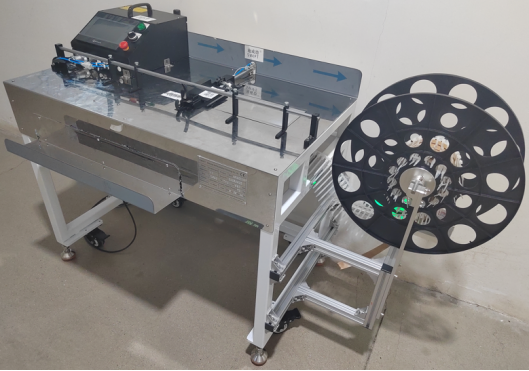

Swift Automation is a leading manufacturer specializing in automatic nylon cable‑tie machines, tools, guns, and complementary equipment. Their solutions are engineered to improve productivity, ensure uniform quality, and enhance safety in cable management operations across industries.

Common Cable-Bundling Challenges

Even experienced technicians face several challenges when bundling cables manually:

-

Inconsistent Tightness: Manually applied cable ties can vary in tension, either leaving bundles loose or applying excessive force that can damage delicate cables or insulation.

-

Time-Intensive Work: Large bundles with multiple cables take considerable time to organize manually, slowing down production or installation workflows.

-

Difficult Access Areas: Tight spaces, high racks, and complex cable pathways make manual tying awkward, increasing the risk of improper bundling or injury.

-

Maintaining Uniformity: Achieving consistent results across multiple bundles, particularly in industrial-scale projects, is challenging without automation.

-

Operator Fatigue and Safety Risks: Repetitive hand movements increase the risk of strain, cuts, or long-term musculoskeletal injuries.

Recognizing these challenges highlights the need for automation to maintain safety, efficiency, and high-quality cable management.

How Automatic Cable‑Tie Machines Solve These Challenges

Automatic cable‑tie machines are specifically designed to overcome the limitations of manual bundling, offering consistent and efficient operation. The machines combine electronic controls, ergonomic design, and precision mechanisms to deliver superior results.

Key advantages include:

-

Consistent Tension and Secure Bundling: Machines apply uniform force for each cable tie, preventing damage to sensitive cables while ensuring tight, reliable bundles.

-

High-Speed Operation: Automatic tying reduces labor time dramatically, making it ideal for large-scale production, high-density wiring systems, or complex assemblies.

-

Ergonomic and Flexible Design: Lightweight guns and compact machines provide access to tight corners, high racks, and hard-to-reach areas, reducing worker fatigue.

-

Repeatable Precision: Standardized bundling improves quality control and minimizes variation across multiple installations.

-

Wide Compatibility: Able to handle cables of various diameters and materials, as well as different tie lengths, automatic machines adapt to a range of industrial requirements.

Swift Automation’s products also incorporate intuitive controls and programmable settings, allowing operators to optimize bundling processes for different cable configurations and project requirements.

Applications Across Industries

Automatic cable‑tie machines are employed across industries where precise, efficient, and safe cable management is critical:

-

Electrical and Electronics Manufacturing: Assembly lines benefit from high-speed, uniform bundling, reducing labor costs and improving production throughput.

-

Data Centers and Telecommunications: Dense cabling networks require organized bundles to ensure proper airflow, maintenance access, and operational reliability.

-

Automotive and Aerospace Wiring Harnesses: Consistent tension and precise placement are essential for safety-critical systems in vehicles and aircraft.

-

Construction and Industrial Installations: Machines speed up on-site cable management while ensuring long-term reliability and compliance with wiring standards.

-

Renewable Energy Systems: Solar arrays, wind turbines, and energy storage systems rely on durable, secure cable ties to maintain safety and efficiency.

In each scenario, automatic cable‑tie machines provide repeatable performance that manual methods cannot match.

Case Study: Improving Efficiency in a Manufacturing Plant

In a mid-sized electronics assembly plant, workers previously spent several hours manually bundling wiring harnesses for each production batch. After implementing Swift Automation’s automatic cable‑tie machines, the plant achieved:

-

50–70% reduction in labor time

-

Elimination of inconsistent tie tension

-

Significant reduction in cable damage and waste

-

Improved operator ergonomics and reduced fatigue

This case demonstrates how automation not only enhances efficiency but also improves product quality and worker safety.

Selecting the Right Cable‑Tie Machine

Choosing the appropriate automatic cable‑tie machine depends on:

-

Bundle Size and Cable Diameter: Machines must accommodate the range of bundle sizes and cable diameters required for the specific application.

-

Production Speed Requirements: High-volume environments need fast machines with automated feeding and tie cycling, while smaller installations may benefit from portable, semi-automatic models.

-

Adjustable Tension Control: Ensures that delicate or high-performance cables are protected while maintaining secure bundling.

-

Tie Material Compatibility: Using high-quality nylon cable ties ensures durability and consistent performance.

-

Maintenance and Durability: Robust machines with simple maintenance routines reduce downtime and long-term costs.

Swift Automation offers a wide selection of models, from hand-held automated guns to fully integrated line automation, catering to diverse industrial needs.

Conclusion

Cable bundling is more than an organizational task; it is a critical factor in safety, operational efficiency, and long-term system reliability. Automatic cable‑tie machines effectively address common challenges such as inconsistent tension, limited accessibility, and time-consuming manual processes.

With Swift Automation’s range of nylon cable-tie machines, tools, and accessories, businesses can achieve faster, safer, and more consistent cable management. By adopting automated bundling solutions, industries improve productivity, reduce operational risk, and ensure high-quality outcomes for complex wiring systems. Automatic cable‑tie machines are not just tools—they are essential assets for modern industrial efficiency and safety.

www.sz-swift.com

Shenzhen Swift Automation Technology Co., Ltd.